FOS-D mofuta oa Automatic Oil lubrication Pumps

Lintlha

Mofuta oa FOS-D ke oa pompo ea ho hanyetsa motlakase, e sebelisoang tsamaisong ea ho hanyetsa.Ke sistimi ea ho tlotsa e nang le khatello e tlase, e arotsoeng ka pompo ea nako le nako le pompo ea ho tlotsa e tsoelang pele.Ea pele e aba oli e tlotsang ho lubrication ka 'ngoe ka ho lekana ka sekotoana sa metering.Ntlha, hlokomela ho lubrication nako le nako, ea ho qetela ke pompo ea ho lubrication e tsoelang pele, oli e tlotsang e abeloa sebakeng se seng le se seng sa lubrication ka tekanyo ka karolo ea taolo ho hlokomela lubrication e tsoelang pele.

E tšoauoa ka sebopeho se kopaneng, ts'ebetso e bonolo le tlhokomelo, 'me phepelo ea oli ea sebaka sa lubrication e laoloa ke likarolo tsa metering kapa likarolo tsa taolo, mme oli e fanoa ka ho lekana.Ea boraro ke hore ho bonolo ho eketsa kapa ho fokotsa ntlha ea lubrication.Qetellong, tiiso e ikhethang Moralo o ka thibela ka katleho ho lutla ho hokahaneng.

Lintlha

Ke pompo ea ho tlotsa e tsamaisang piston ho khutlisa le ho tsamaisa oli ka matla a makenete a motlakase a hlahisoang ke lebala la motlakase.E na le litšobotsi tsa sebopeho se utloahalang, ts'ebetso e ka tšeptjoang, ponahalo e ntle, mesebetsi e feletseng le ts'ebetso e phahameng ea litšenyehelo.E ka nka sebaka sa pompo ea piston ea motlakase 'me e loketse ho tlotsa lisebelisoa tse nyane tsa mochini tse nang le lintlha tse fokolang tsa ho tlotsa.

Parameter ea lihlahisoa

| Mohlala | Phallang (ml/mots) | Ente e kholo khatello (MPa) | Ho tlotsa ntlha | Viscosity ea oli (mm2/s) | Motor | Tanka (L) | Boima ba 'mele | |||

| Votage | matla (W) | maqhubu (HZ) | ||||||||

| FOS-R-2II | Atomatic -Volumeteric | 100 | 2 | 1-180 | 20-230 | AC220 | 20 | 50/60 | 2 | 2.5 |

| FOS-R-3II | Atomatic -Volumeteric | 3 | 3.5 | |||||||

| FOS-R-9II | Atomatic -Volumeteric | 9 | 6.5 | |||||||

| FOS-D-2II | Atomatic -Khanyetso | 2 | 2.5 | |||||||

| FOS-D-3II | Atomatic -Khanyetso | 3 | 3.5 | |||||||

| FOS-D-9II | Atomatic -Khanyetso | 9 | 6 | |||||||

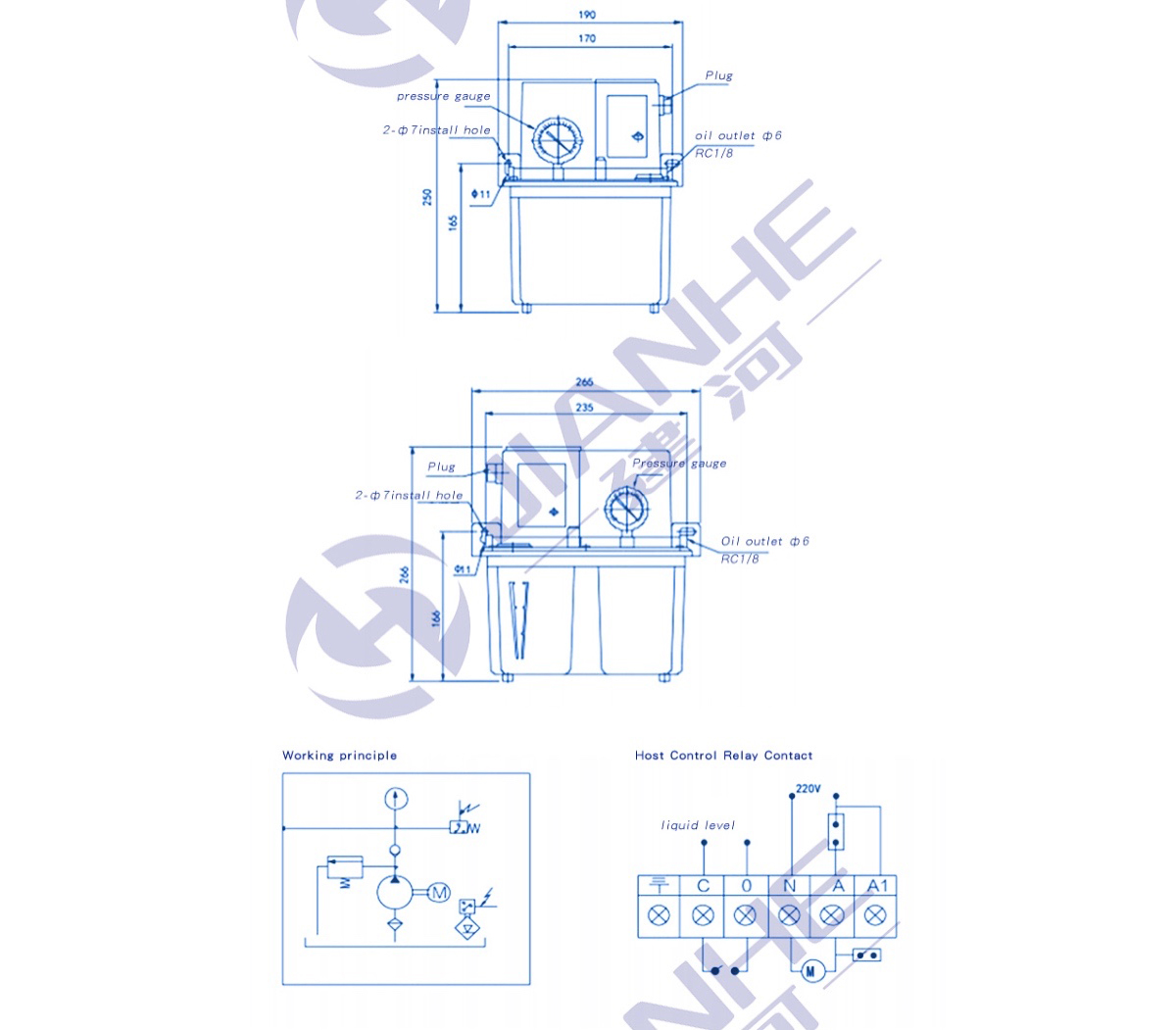

Sebopeho sa pompo ea oli e itlotsang ka boiketsetso bakeng sa lisebelisoa tsa mochini oa CNC:

E na le switch ea boemo ba mokelikeli, selaolo, le switch ea jog.Ho latela litsamaiso tse fapaneng, sesebelisoa sa khatello le sona se ka hlophisoa.Letšoao le laoloang le ka boela la hokahana ka kotloloho ho moamoheli oa mosebelisi PLC.E khona ho hlokomela ho lekola boemo ba oli ka tankeng ea oli le khatello ea sistimi ea phano ea oli le ho beha potoloho ea lubrication.

Sehlahisoa sena se sebelisoa haholo lits'ebetsong tse fapaneng tsa lubrication ea lisebelisoa tsa mochini, forging, textile, printing, plastics, rabara, kaho, boenjiniere, indasteri e bobebe le lisebelisoa tse ling tsa mochini.